The Ecodesign Maturity Model (EcoM2) is a strategic framework that supports manufacturing companies to have a consistent and systematic ecodesign implementation, enabling them to realize the business benefits related to the development of more sustainable products and services.

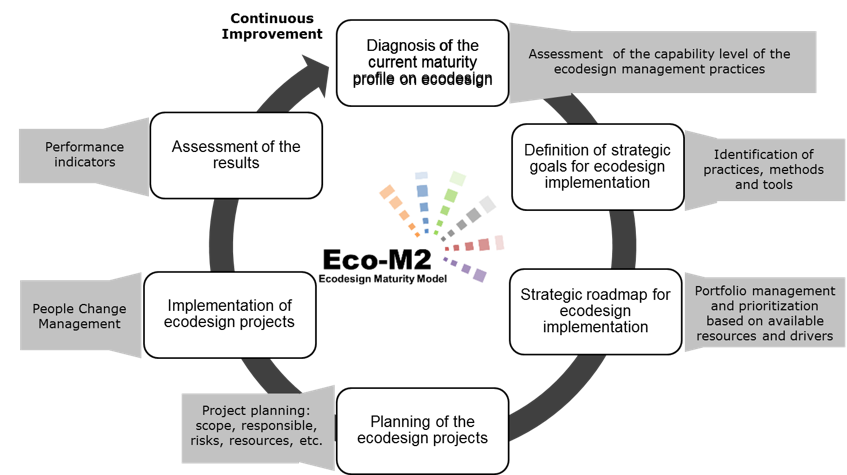

Based on a diagnosis of the current maturity profile of a company’s product development and related processes regarding ecodesign implementation, the EcoM2 proposes the most suitable ecodesign practices and improvement projects to be applied, by adopting a continuous improvement approach for process improvement.

The EcoM2 methodology provides a systematic and consistent approach for ecodesign implementation into manufacturing companies by allowing them to:

- Benchmark and evaluate strengths and improvement opportunities by means of a detailed diagnosis of the current maturity profile of their current processes to tackle and integrate ecodesign;

- Define a basis for setting the strategic goals and deploying strategic roadmaps for systematic ecodesign integration;

- Establish a common language and a shared vision for systematic ecodesign deployment in the organization;

- Obtain a framework for continuous improvement, ensuring consistency in the product development and related processes; and

- Devise a systematic approach for measuring progress, bringing a long-term perspective for ecodesign implementation.

- The EcoM2 solutions will ultimately lead our customers to a consistent ecodesign implementation, enabling them to realize the ecodesign-related business benefits.

The EcoM2 has had its proof of concept demonstrated by academic validation and by its successful application in large manufacturing companies (Grundfos, LEGO Group, Coloplast, Philips Healthcare, Tecumseh, Natura and Embraer).

Fore more information about the EcoM2, contact us.